Recent blog posts have revolved around the ideas of Corporate Social Responsibility and Supply Chain Sustainability. We’ve talked about the Nike supply chain disaster and the millennial impact on today’s supply chain. Having sustainability in your supply chain is no longer something that is “nice to do.” Instead, it is quickly becoming a necessary part of every business model.

Some organizations are adjusting their practices to make customers happy and attract more of the market. While others are making changes solely because of new regulations coming into play. Regardless, the demand for sustainability is increasing more and more as we head into the next few years.

Why should you change?

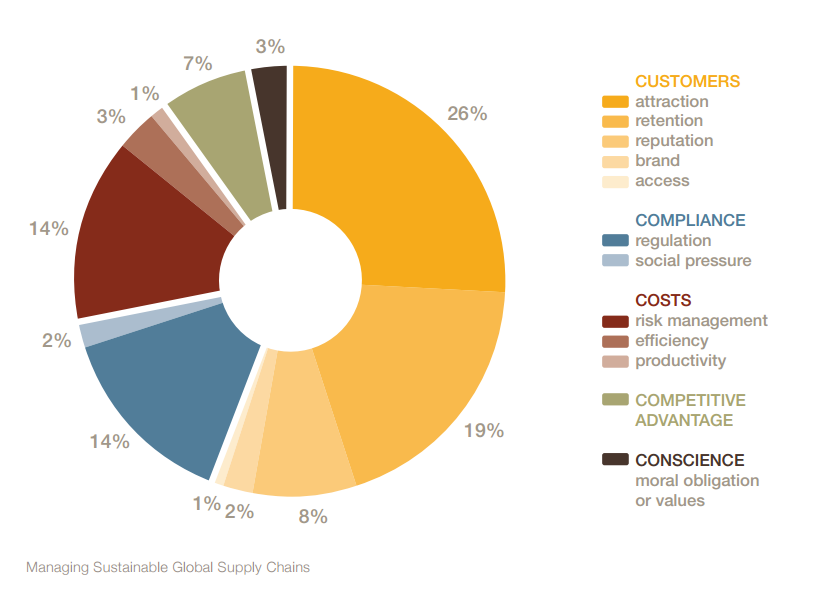

Reasons for change can be motivated by any number of factors, but it is important to highlight which specific ones may impact you the most. A report published by the Network for Business Sustainability titled “Managing Sustainable Global Supply Chains” discusses the different motivators for change. This report classifies them into five main categories: Customers, Compliance, Costs, Competitive Advantage, and Conscience. It discusses the importance of change within supply chains, reasoning, and how this can help you improve. Here’s some of the reasons why people are moving towards this change:

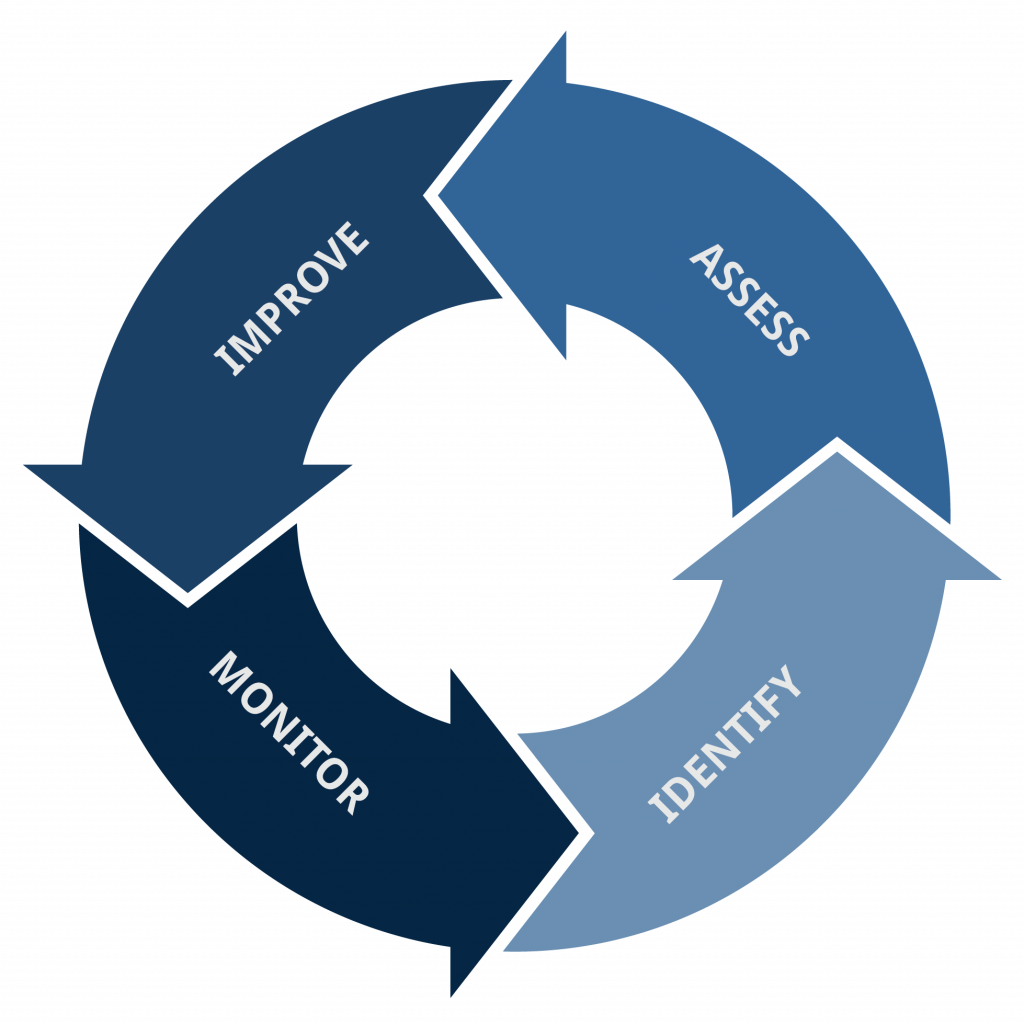

Fully understanding your motivation for change is important when working towards supply chain sustainability. It is often the first step in the ongoing process. First, a company needs to identify a cause for change. Next, they should assess what capabilities they have internally and externally to make this shift. Finally, they should take action and implement ongoing monitoring to maintain their practices. This process has a circular motion with no defined end. Just like the environment they are in, organizations need to be flexible to adapt to new standards and demands.

What does it take to change?

After a company identifies its reason(s) for change, it needs to look at its own capabilities internally and externally. You need to determine how you are able to change your processes. Are there policies already in place that support these changes? Is there leadership at the firm that has a strong background in sustainability? Is there an opportunity for industry collaboration that aligns with the changes you are hoping to make?

Being aware of the opportunities and resources available can help you determine what your first few steps will be. From there, you have to continually build on those until you start to see improvement. You can use your resources as a guide to build the path. The ‘assess’ and ‘improve’ steps go hand in hand. You have to continually be assessing what is available to you in order to determine what your next step is.

Always moving forward

Finally, understand that making changes to a supply chain does not end once you reach a satisfactory level. This is because neglecting these changes will result in taking steps back. You must determine how to monitor these improvements to ensure they are maintained. For some companies, this could mean sending someone out to company warehouses once a month once the location meets the standard. For others, this could be putting an evaluation system in place for suppliers that they must meet.

It is also important at this stage to recognize that the environment is always changing. The improvements you made one year ago may not be enough a few years down the line. Regulations and customer demand are two of the most dynamic factors in this equation. Standards and expectations are constantly being raised, and companies must meet or exceed them. There is no longer have a choice when it comes to social responsibility in the supply chain. For an organization to be successful, they need to ensure they are meeting regulations and customer demands.