Back in March of 1971, Starbucks was founded selling whole roasted coffee beans from a single location in Seattle’s Pike Place Market. Today, it has over 26,000 coffeehouses worldwide and brought in over $22 billion in revenue last year. However, things didn’t always look so bright.

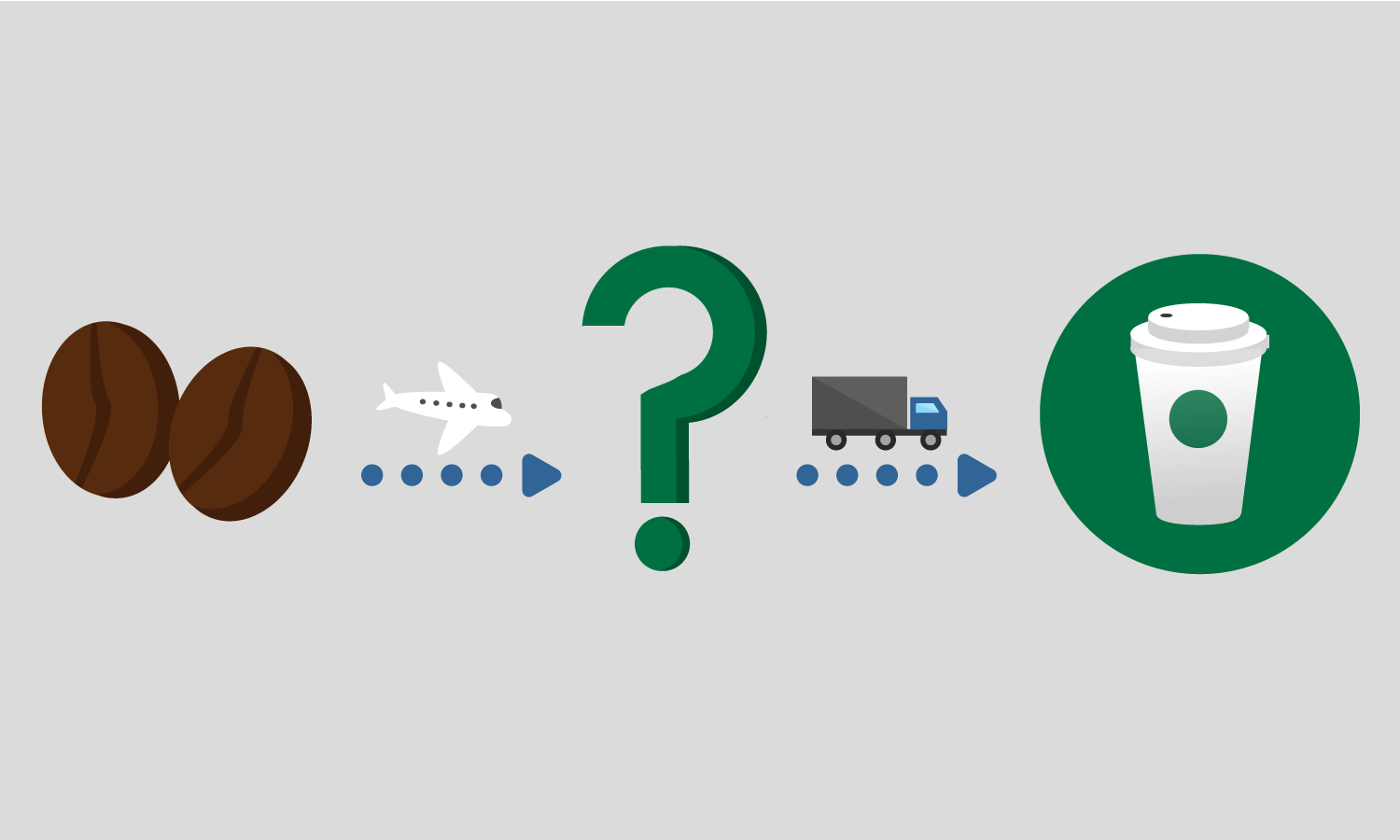

Back in the 2000s, Starbucks had a problem. As the company was growing at a staggering rate, Starbucks’ supply chain was struggling to keep up. The financial crisis of 2008 only made the matter worse. Between 2007 and 2008, supply chain costs in the US rose $75 million even though sales for US stores dropped 10%. At this point, it was clear that change was necessary. As a result, Peter Gibbons was brought in and completely transformed the supply chain. Here’s three strategies he used as executive vice president of Global Supply Chain Operations:

Reorganization

With a centralized system, Starbucks has total control over their distribution centers across the globe. Since they source beans from three continents, a unified system works well. One of Gibbon’s first steps was to sort supply chain steps in four groups: plan, source, make, and deliver. His goal was to simplify the complex chain into one cohesive system.

Gibbons also began using a binary scorecard system to assess activities. There are four categories: safety in operations, on-time delivery and order fill rates, end-to-end costs, and enterprise savings. Using clear metrics, Starbucks could focus on improvement.

Tech and Innovation

Using a cloud-based inventory system provides info in real-time. With this system, Starbucks’ supply chain has more flexibility in planning and scheduling. They can respond to changes in demand quickly and efficiently. Not only do they manage inventory through the cloud, their CRM and ERP systems are also cloud-based. Keeping up with evolving tech helps Starbucks to grow as a business.

Back in 2014, Starbucks and other specialty coffee producers were facing a major supply chain threat. Due to the spread of a fungus, coffee production was down and prices were up. Starbucks’ response was to buy a farm in Costa Rica to learn more about the fungus. Furthermore, they spend one fifth of their annual income on innovative strategies such as the farm.

Ethical Sustainability

Starbucks prides themselves in sourcing ethically in a sustainable way. The company has set standards that potential suppliers must meet before approval. These policies take form in sourcing, social responsibility, etc. Also, Starbucks’ supply chain goals include having 100% ethically sourced tea and cocoa by 2020. Taking these steps ensures the quality of their product, not just in taste but in the impact it leaves on the world. Building over 1,200 LEED stores, they account for over 20% of total global LEED projects.

There’s no question why Starbucks made Gartner’s Top 25 Supply Chains. Over the years, they have faced supply chain obstacles head-on and won. Although not all of these strategies may work for you, we can all learn from their commitment to improving supply chain.

If you’d like to learn more about the benefits of cloud-based inventory systems, click here.