Green supply chain practices obviously offer environmental benefits, but these green initiatives have significant economic value as well. Nowadays, it should come as no surprise to businesses that their customers value eco-friendly products.

In fact, at least 70% of consumers say they are willing to pay a 5% price premium for more sustainable goods. But companies are not only facing rising pressure from their customers to go green. Investors and regulators are also keeping a close eye on the environmental effects of business operations.

For example, the US Securities and Exchange Commission proposed new rules that will require US companies to openly share data about their greenhouse gas emissions. This kind of transparency not only directly impacts a company’s reputation but also influences investor decisions.

As a result, more and more businesses are investing their time and money into rethinking their entire supply chain. Not just the environmental impact of their own operations, but their partners’ and suppliers’ operations, too.

Read on to find practical solutions for a greener supply chain and a healthier bottom line.

What is Green Supply Chain Management?

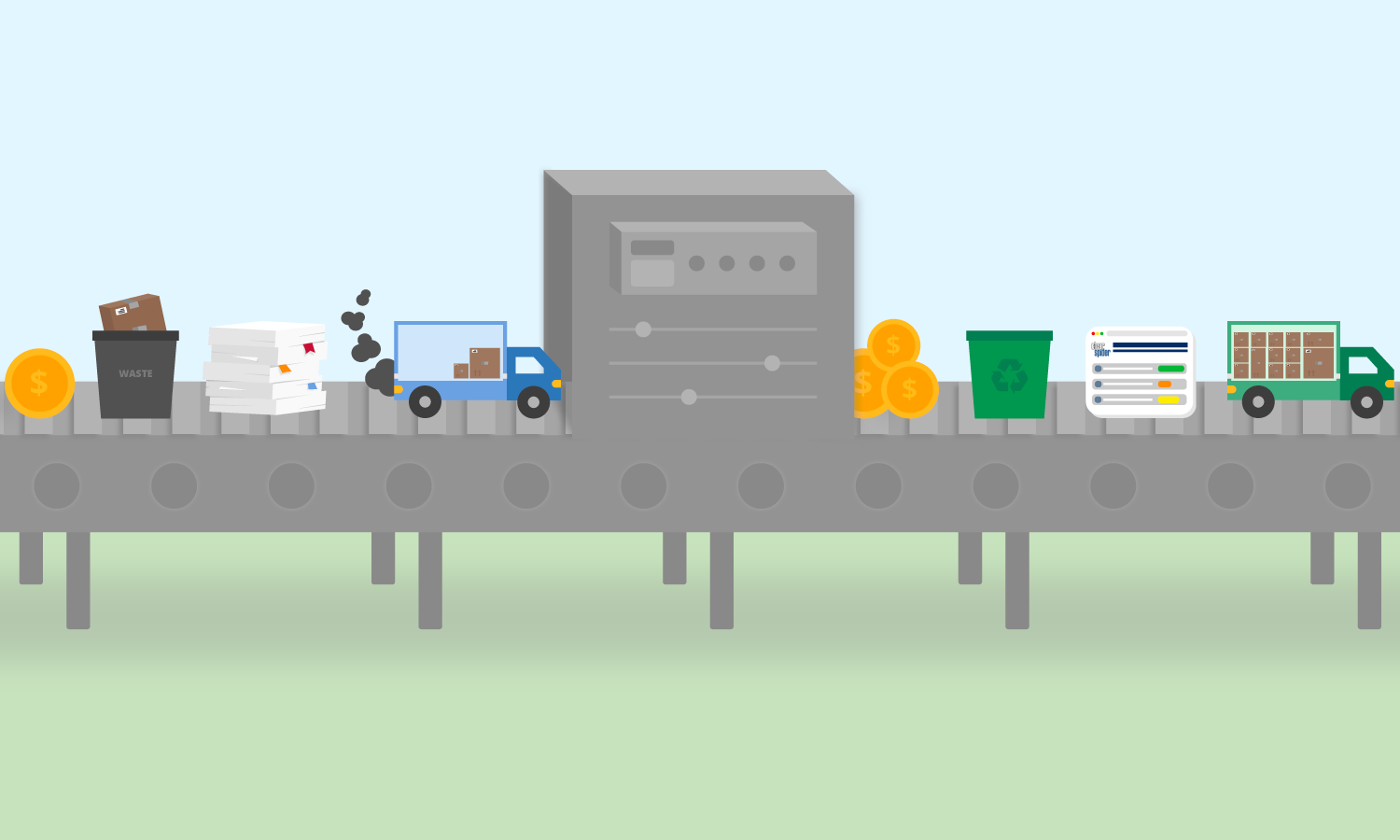

Traditional supply chains are full of inefficiencies. By switching to greener operations, companies can turn these inefficiencies into opportunities to reduce waste and increase profits.

Green supply chain management uses eco-friendly practices to minimize air, water, and waste pollution. These practices, in turn, help your business operate more efficiently and sustainably. Green improvements can be made at every stage of your supply chain, from purchasing to transportation.

Green Purchasing

Uses local suppliers with green initiatives to reduce shipping distance, and reduce fuel consumption and emissions.

Green Manufacturing

Uses efficient equipment powered by clean and renewable energy to consume less energy, release fewer pollutants, and reduce fuel costs.

Green Packaging

Uses efficient packaging designs with recycled materials that consider every phase of a package’s lifecycle including consumer disposal.

Green Warehousing

Uses a warehouse management system (WMS) to optimize warehouse layout and operations, reducing the amount of energy consumed by order fulfillment.

Green Transportation

Uses optimized delivery routes and bulk shipping to reduce your fuel consumption, your fuel costs, and your carbon footprint.

Think Lean to Go Green

Lean inventory management is a greener approach to managing your inventory. It focuses on improving the efficiency of your supply chain operations for the purpose of reducing waste. A company that uses a lean inventory approach holds only what is necessary at all stages of production. This saves money, reduces waste and enables companies to provide more value to their customers.

The challenge is that lean inventory management requires robust inventory visibility that most businesses struggle to achieve. Without this visibility, it’s extremely difficult to make a successful transition to leaner and greener operations. That’s where powerful inventory management comes into the picture.

How Clear Spider Makes a Difference

Clear Spider’s powerful system gives you full, 24/7 visibility of your entire inventory. This allows you to make data-driven changes that are better for your business, your investors, your customers, and the environment. Inventory is a huge part of your operations. Clear Spider’s flexible inventory solutions are designed to take the guesswork out of finding the best ways to manage yours.

Start saving by going green with Clear Spider. Get Started!

There’s No Planet B

There’s no question that green supply chain practices play an essential role in ensuring a healthy future for our planet. It’s important to remember that these same environmental benefits also reduce risk to your business and to your investors. Sustainable practices are, as their name suggests, sustainable. They will not deplete the resources your business relies on in order to continue operating.

Green practices protect your company’s future by:

- conserving energy and resources for future use

- reducing waste and packaging costs by using recyclable materials

- unlocking new revenue streams by saving damaged goods to make new goods

Clear Spider’s Top 5 Strategies for a Green Supply Chain

With real-time inventory visibility, Clear Spider’s solutions provide a clear picture of:

✔ The entire lifecycle of each item in your inventory

✔ The efficiency of each of your inventory processes

Clear Spider’s flexible system makes it easy for companies to achieve greener operations that lead to long-term savings.

1. Boost Warehouse Efficiency with Clear Spider’s Warehouse Management System

- fewer returned items thanks to improved order fulfillment accuracy

- always ship orders from the nearest warehouse with multi warehouse tracking

- design efficient pick paths to achieve an optimized warehouse layout

- save time and reduce energy usage and costs on order fulfillment and shipping

2. Enhance Data Sharing with Clear Spider’s Vendor Managed Inventory (VMI)

- support effective coordination of green initiatives between a vendor and its customers

- reduce wasteful, obsolete stock by improving traceability

- improve lead-times and reduce stock outs by maintaining the correct flow of inventory in your supply chain

3. Customize Your Clear Spider System with Solutions and Features that Increase Your Operational Efficiency

- reduce packaging, energy usage and the number of delivery trucks on the road with our Kitting feature

- reduce the number of trips made for deliveries by optimizing cargo space in delivery trucks with our Field Service Inventory Management

- reduce expired food, medical, and other perishable items with our Lot Control and Shelf Life feature

4. Reduce Waste Across Your Supply Chain with Clear Spider’s Inventory Management System

- reduce waste by increasing supply chain visibility and tracking inventory through all returns processes

- reduce waste and increase profits by identifying items for re-use or re-sale

- reduce paper waste by using our Barcode Scanning and Automatic Replenishment features

5. Automate and Streamline Your Entire Supply Chain

- reduce supply chain delays, order backlogs, and costly last-minute shipments

- reduce your manual labor costs, equipment operation time, and energy consumption by boosting employee productivity

- reduce in-office energy use and waste production with our Mobile Solutions that allow employees to work from anywhere, at any time, on- or offline

Reap What You Sow

Improving your company’s environmental performance is proven to significantly improve its economic performance.

Benefitting Your Bottom Line

Lower Costs, Higher Profits

Green supply chains increase efficiency and decrease energy use. Companies increase profits by lowering operating and energy costs, adding price premiums, and by gaining access to additional customer segments.

Enhanced Public Image and Brand Value

Today’s consumers are aware of the significant environmental impacts traditional supply chains have on the health of the environment. As a result, they actively seek out brands that make the effort to go green. Adopting green supply chain practices enhances your brand’s public reputation. Your brand will not only attract new customers, but also increase your customer retention, loyalty, and satisfaction.

Lower Risk, Higher ROI

Nowadays, investors expect more than just high economic performance. They are scrutinizing the social and environmental effects of their businesses as well. Proactively switching to greener practices increases a company’s investment attractiveness and decreases regulatory risks imposed by new government policies. This ultimately improves market performance and increases stakeholder returns.

Stand Out from the Competition

When searching for a product or service, 4 out of 5 consumers are choosing the more sustainable option. Switch to green supply chain practices and re-brand your business as a leader of positive change. This is guaranteed to help you stand out in your customers’ minds. Green improvements also improve employee morale, making it easier for businesses to attract and retain talent.

So, Does It Pay To Be Green?

Global leaders are joining a growing list of companies choosing to invest in green alternatives to traditional supply chain practices.

Below are just a few examples of how green thinking results in both a healthier environment and a healthier bottom line:

Staples

The company saved $3 million annually by using 20% less fuel. It simply limited the maximum speed of their delivery drivers to 60 mph.

PepsiCo

Water conservation efforts saved PepsiCo more than $80 million over 4 years. It also de-risked its operations by reducing its reliance on water, a natural resource that experiences unpredictable changes.

Honeywell

Clear Spider’s cloud-based system gave Honeywell 100% visibility. We seamlessly integrated our mobile asset logging and Honeywell’s existing systems into one central data hub. The payoff of this transformation was higher production yields, minimized waste, and reduced costs.

Good Logistics Are Green Logistics

Minimize your environmental impact while maximizing your profits with Clear Spider’s powerful and easy to use system. Click here to achieve sustainable growth that’s good for both your business and the environment.