Vendor Managed Inventory, or VMI, is where the vendor has control over the stock supplied to their customer. The vendor is responsible for analyzing and optimizing the inventory flow for each of their VMI customers. For some, this is a familiar concept. If it’s not you can find more about it here. But, the question people are asking now: “Is Vendor Managed Inventory right for me?”

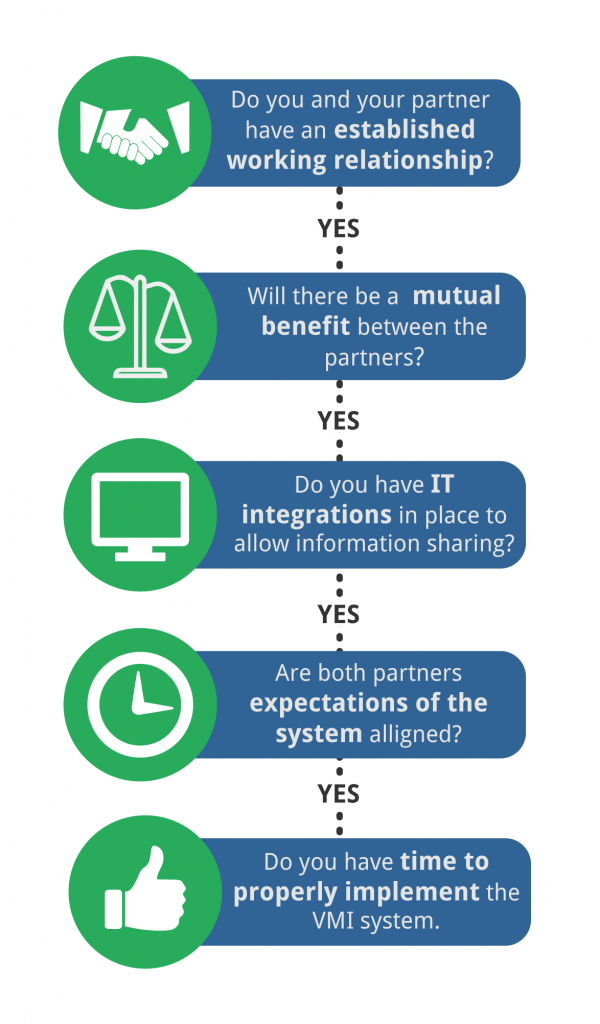

There are many proven benefits that come from VMI, however it may not be right for everyone. There are a few things that you should keep in mind before entering into a VMI relationship. Both partners need to ensure they have an established working relationship. Both of these partners also need to be able to see a mutual benefit from a VMI system. Individually, the two parties need to have organizational processes in place to allow info sharing. There needs to be a discussion to make sure both partners’ expectations of the system are aligned. Finally, there needs to be enough time to ensure the system is properly and thoroughly implemented.

Established Working Relationship

It is essential that the partners looking to implement a VMI system have this. The parties involved need to have a sufficient level of trust and communication. This is because VMI is dependent on these aspects. Both parties will access and update the same system. If the partners do not have a solid foundation to build the VMI system into, it could hinder their ability to find success.

Mutual Benefit

When entering into VMI, there should be a mutual benefit for the two parties involved. The customer will mainly see benefit in the alleviated responsibility. Along with this shift in order planning and processing comes a shift in costs. This helps to decrease operational costs for the customer. For the vendor, the benefit of VMI is in the increase in control. Since they have access to more info, they are able to more accurately forecast demand for their customers and their own production and ordering. This allows them to focus on efficiency, lean manufacturing, and seamless delivery.

Organizational Processes

In a VMI relationship, info needs to be constantly shared and updated across one channel. This takes a lot of organization to run smoothly and efficiently. So, each organization should have competent processes in place to gather and report inventory data independently. If not, you should consider improving basic operational processes first.

Expectations of the System

It is crucial that both partners understand and accept each other’s expectations. Early on, the vendor and customer should clearly outline these along with specific performance metrics. They should understand each other’s business models and company visions. It is important to do this early so that both parties are working towards one common goal from the start.

Time to Properly Implement

Setting up a VMI system can take some time to do properly. However it can take even more time to fix it if set up incorrectly. Ensure you have the time to be thorough so that you can do it right the first time. Taking your time is essential to ensure a smooth transition. Do not rush the process! Start small and work your way up to a more complex system. Don’t forget poor system implementation can have major consequences.

Before implementing a VMI system, be sure to get advice from industry peers and other experts. Do your own research as well to ensure you are fully ready for the transition. VMI may not be for everyone, but it can greatly help if it is right for you!

Are you interested in learning more about VMI and figuring out if it is right for you? Be sure to take a look at our Whitepaper on VMI.